Lundhags – T-Skate

- Achievments:

-

Recycled Steel

- Recycled Steel

-

- > View all 'Recycled Steel' evaluations

× -

Recycled Aluminium

- Recycled Aluminium

-

- > View all 'Recycled Aluminium' evaluations

× -

Great Repairability

- Great Repairability

-

- > View all 'Great Repairability' evaluations

× -

Recyclable

- Recyclable

-

- > View all 'Recyclable' evaluations

×

Product description by Lundhags

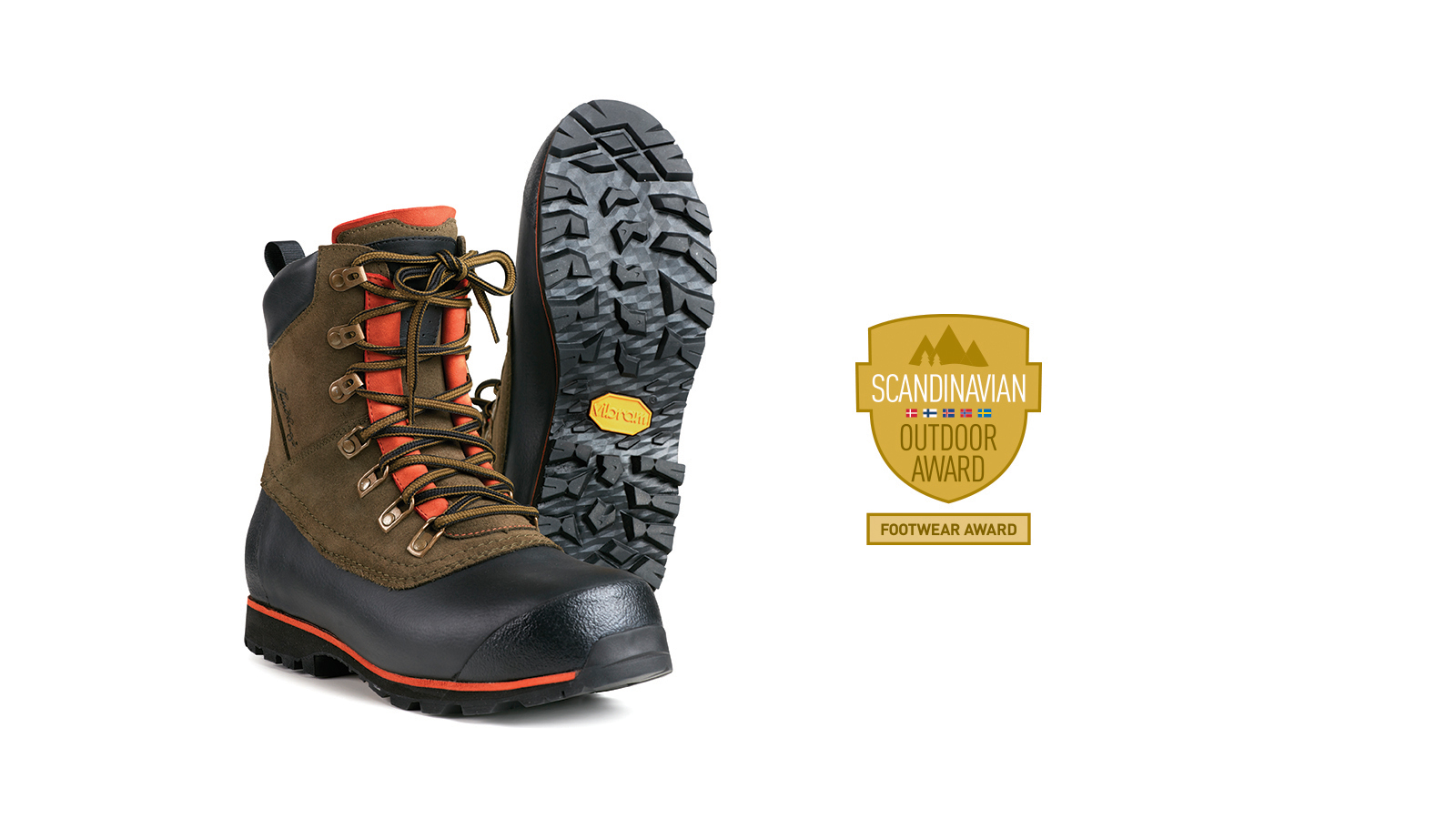

All-round skate with an innovative pivot hinged blade attachment. The T-skate has the same 28-meter skating radius regardless of the temperature. 100% Swedish made from recycled material and 100% recyclable.

- All-round touring skate

- 100% Swedish-made

- 100% recyclable and made from recycled materials

- Innovative pivot hinged blade attachment

- Skating radius of 28-meters, the same radius regardless of the temperature

- Blade made of stainless steel from Sandvik

- Hole profile and balance point adjusted for Rottefellas bindings and SNS bindings

- CNC-milled profile

- Laser cut and CNC sharpened blade

- Weight 680 g

GRV’s View:

This is a traditional locally made niche product from Sweden with maximum transparency and 100% recyclability.

- Customer Service:

- Product Information

BEST

11 / 15

GRV Transparency ToolLundhags - T-Skate

2017

Management

Management Commitment

Commitment Product

ProductBrand Management

- Lundhags is a traditional company with a focus on product quality.

- Long-term personal relationships to manufacturers stabilize the supply chain management and help to implement a code of conduct to respect workers rights and minimize environmental impacts.

- Dedicated staff follows a five-year plan to gain deeper knowledge on chemical impacts and other emissions.

- One Season Program: Lundhags is pioneering a new way of seasonal planning.

- Products are designed to be easily repairable and long lasting.

- No end of use strategy jet

Brand Commitment

- The definition of environmentally friendlier materials is to have either recycled and/ or preferred materials.

- Social audits are done by Lundhags personally, as they entertain long lasting, personal relationships to manufacturers. In regards to the focused portfolio this is an acceptable business practice.

- Lundhags takes part in Multi-stakeholder initiatives and has a lively dialogue with customers and outdoor actors to get feedback on product performance.

- No reporting yet. A five-year plan is in place to structure and measure CSR.

Product

- Locally made product from Sweden.

- Recycled steel and aluminum account for 50% of recycled content.

- Easy disassembly and therefore very good reparability as well as recyclability.

- Very high traceability and transparency.

- Brand Management

- Brand Commitment

- Product

Brand Management for us at GRV means to look at all the issues, which are directly controlled and integrated by the Brand’s Management towards business and supply chain strategy as a whole.

With Brand Commitment GRV is looking at the pro-active efforts towards sustainable development on all levels like the % of sustainable product lines within the whole portfolio, or life cycle assessments and public reporting. These are key indicators of the engagement of a Brand towards responsibility.

On this level GRV is looking at product related information, like material content, supply chain and certification. Warranty, reparability and “end of use” advice are also important aspects. At the moment, GRV is looking at selected highlight products from different product lines, which show the special sustainable efforts of the brand. Here is the overview of the products we looked at, if you want to know the details, go to the specific products.

/ 5

Integration of sustainability

Lundhags has two specially educated people to look after CSR within the company.

less

They have formulated a new sustainability strategy with five-year goals on four focus areas. Transparency is one of the goals.Certificates, Standards and Guidelines

No 3rd party certificates which are directly linked to Lundhags, but dedicated people check the quality, environmental and social conditions first hand. For quality management they follow the guidelines of their internal handbook. In regards to the size and tradition of Lundhags this is a feasible strategy.

lessDesign Process

Focus is on durability. Versatile, high function products, which are easy to repair. In 2018 Lundhags has started the One Season Program. This program has two aspects: There is only one collection per year, which means that Lundhags retailers can view the whole year ahead and decide at different order slots for summer and winter which product to order. The internal advantages are, that Lundhags has more time to spend on design and maturity of a product and more time to test it before it hits the market.

This results in very good planning for all parties involved, which means lesser ecological impacts on many levels as well.

lessEmission Management & Product Transport

They measure all transportation related CO2 emissions and have a continuous improvement-plan in place to reduce the impact by selecting as many process steps as possible as locally as possible.

All Lundhags facilities in Sweden use energy from renewable resources, as this type of energy is easily available there.

lessSourcing Philosophy

They follow the stringent guidelines of their Code of Conduct and their RSL (Restricted Substance List) with all suppliers. Lundhags engages long-time relationships with CMT manufacturers (cut, make and trim). Almost all fabrics and trims are nominated. This means these are specified materials, which have been selected by Lundhags beforehand.

lessRepair & End of Use

All products are designed to be easily repairable. Lundhags works with local repair centres, some of the repair happens in-house. Especially the shoe design allows for exceptional repair possibilities. No end of use solution so far, but this is part of the five year plan: Lundhags is about to establish an end of use platform (take back) in their repair shops and wants to make more product from left overs.

lessEnvironmental & Social Projects

Lundhags makes some smaller efforts like helping refugees. Many members of the staff are dedicated in their private life to support different projects. Mobile bike repair helps to make sure, that Lundhags staff has functional bikes to commute to work.

lessEvent Management

Due to the new business strategy to only feature one collection a year the need for sales meetings and sales travels are significantly reduced.

less

The new trade-show booth is made from untreated wood and steal to be used for at least five years.

Promotion material is slowly replaced by digital.Packaging & Labelling

FSC certified paper, no water based inks, unbleached paper and cardboard.

Material Program & Testing

Externally nominated lab tests and a team to do field tests. Cooporation with Sverea (Swedish test and certification organisation). Besides working with an RSL (Restricted Substance List) it is within the five year plan to gain a deeper knowledge to track and monitor chemical impact.

Lundhags is part of the same group as Swix and Toko which gives Lundhags chemical support for the fabrics line.Lundhags systematically looks at all material groups and tries to achieve better environmental results by replacing them with better alternatives if possible.

less

Life Cycle Assessment

Planned for Makke Pants in 2018.

Reporting

Besides the GRV Transparency Tool, Lundhags is planning to do an environmental and social report according to GRI in 2018.

Definition of “environmentally friendlier” products and their share in the portfolio

Focus is definitely on long lasting products and performance. Lundhags definition of environmentally friendlier products is to have mostly preferred materials:

less

which are recycled fibres, materials coming from renewable and /or ecological resource (like organic cotton, mulesing free merino wool, etc).Brand's Definition of social responsibility

Lundhags believes that work should be valuable and is not a bargain. Therefore Lundhags is working on transparency to identify if all workers along the supply chain have access to living wages.

Innovation

Just starting the process of measuring fields of action like innovation amongst other things, first results are expected in 2018/19.

Credibility

Lundhags organizes tours with bloggers and journalists to get first hand feedback. They are engaged in a lively dialogue with outdoor actors and enthusiasts.

less

Multistakeholder initiatives include the Scandinavian outdoor group, the water initiative and EOG (European Outdoor Group).

Sourcing Strategy, Material & Supply Chain 1,2,3… Tier

Assembly in Sweden, steel and aluminum are the main components and are sourced in Sweden. Steel and aluminum make for 50% of recycled content.

Recycling

Easy to dissemble and therefore very good reparability as well as recyclability.

less

The T-skate (skate only) can be dismounted and recycled to 100%. Local materials, local production and local dismounting and recycling, which is exceptionally good!Traceability

Very high traceability and transparency.

Social & Environmental Management

Sweden is a low risk country.

Maintenance & Care

Advice: Steel edges need to be sharpened to last. Lundhags gives a two-year guarantee and also has a repair and sharpening service.

Evaluated Products

Lundhags was founded 1932 in Jämtland by shoemaker Jonas Lundhag. The company is based in Järpen (Jämtland) and Stockholm, Sweden.

They specialize in outdoor clothing, boots and equipment and employ currently 34 people in the company.

Lundhags values: Authentic, functional, sustainable and nordic.